Koraliki Toho/ Multi-Shape/ Color Mix/ Kintaro-Gold Mix 10g/ TOTX01-3206

16,60 zł

Przed obniżką: 17,85 zł

Najniższa cena z 30 dni: 15,17 zł

16,60 zł

Przed obniżką: 17,85 zł

Najniższa cena z 30 dni: 15,17 zł

5,02 zł

Przed obniżką: 5,40 zł

Najniższa cena z 30 dni: 4,59 zł

4,68 zł

Przed obniżką: 5,03 zł

Najniższa cena z 30 dni: 4,28 zł

9,65 zł

Przed obniżką: 10,38 zł

Najniższa cena z 30 dni: 8,82 zł

9,29 zł

Przed obniżką: 9,99 zł

Najniższa cena z 30 dni: 8,49 zł

9,29 zł

Przed obniżką: 9,99 zł

Najniższa cena z 30 dni: 8,49 zł

7,59 zł

Przed obniżką: 8,16 zł

Najniższa cena z 30 dni: 6,94 zł

9,29 zł

Przed obniżką: 9,99 zł

Najniższa cena z 30 dni: 8,49 zł

16,14 zł

Przed obniżką: 17,36 zł

Najniższa cena z 30 dni: 14,76 zł

9,29 zł

Przed obniżką: 9,99 zł

Najniższa cena z 30 dni: 8,49 zł

7,59 zł

Przed obniżką: 8,16 zł

Najniższa cena z 30 dni: 6,94 zł

11,00 zł

Przed obniżką: 11,83 zł

Najniższa cena z 30 dni: 10,06 zł

5,87 zł

Przed obniżką: 6,31 zł

Najniższa cena z 30 dni: 5,36 zł

64,21 zł

Przed obniżką: 69,04 zł

Najniższa cena z 30 dni: 58,68 zł

4,04 zł

Przed obniżką: 4,34 zł

Najniższa cena z 30 dni: 3,69 zł

18,73 zł

Przed obniżką: 20,14 zł

Najniższa cena z 30 dni: 17,12 zł

8,81 zł

Przed obniżką: 9,47 zł

Najniższa cena z 30 dni: 8,05 zł

8,81 zł

Przed obniżką: 9,47 zł

Najniższa cena z 30 dni: 8,05 zł

8,81 zł

Przed obniżką: 9,47 zł

Najniższa cena z 30 dni: 8,05 zł

8,81 zł

Przed obniżką: 9,47 zł

Najniższa cena z 30 dni: 8,05 zł

4,50 zł

Przed obniżką: 4,84 zł

Najniższa cena z 30 dni: 4,11 zł

8,81 zł

Przed obniżką: 9,47 zł

Najniższa cena z 30 dni: 8,05 zł

8,81 zł

Przed obniżką: 9,47 zł

Najniższa cena z 30 dni: 8,05 zł

7,82 zł

Przed obniżką: 8,41 zł

Najniższa cena z 30 dni: 7,15 zł

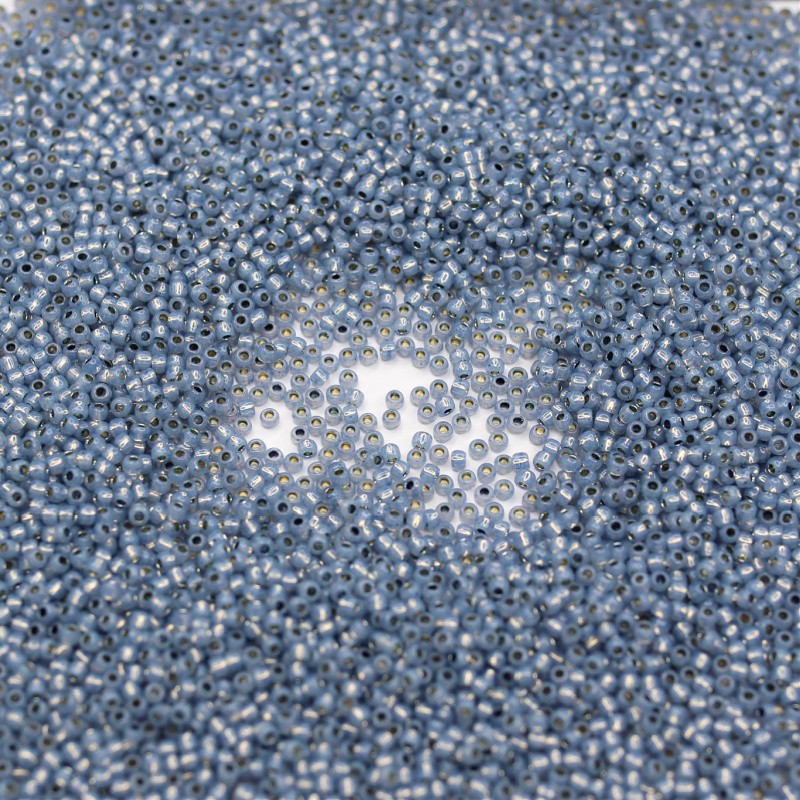

Koraliki Toho to jedne z najbardziej rozpoznawalnych półfabrykatów do biżuterii na świecie. Kojarzymy je nie tylko z nienaganną jakością wykonania, ale też z gigantycznym wyborem kolorów i wykończeń. Perfekcyjnie równe rozmiary tych drobnych, szklanych koralików szybko sprawiły, że zakochały się w nich rękodzielniczki z całego świata. Wiele twórczyń, które po latach korzystania z tańszych koralików postanowiło wypróbować tej japońskiej klasyki, było zdumionych. Ciężko uwierzyć jak wielką różnicę w projektowaniu, tworzeniu i noszeniu biżuterii mogą zrobić koraliki z najwyższej półki.

Historia tworzenia japońskich koralików ze szkła rozpoczęła się już w 1930 roku w okolicach słynnej Hiroszimy. Pierwszą firmą produkującą koraliki była „Mom-and-Pop”. Później, trzeciego listopada 1952 roku w Hiroszimie powstała firma Toho, która dość szybko zdobyła światową popularność. Od tego czasu pracownicy Toho nieustannie starają się doskonalić techniki produkcji szklanych koralików.

Wartości firmy są zgodne z japońskim etosem pracy. Toho zakłada staranne służenie społeczeństwu, dążenie do zmian i pielęgnowanie ich, a także dostosowanie się do globalnych wymagań. Co ciekawe, idee te nie są nastawione jedynie na zysk, czy dobrobyt firmy, ale też mają zapewnić czystość umysłu wszystkich jej pracowników. Ponadto, w tej firmie jakość stawiana jest na pierwszym miejscu. Wszystkie produkty Toho, czyli koraliki, nici i inne testowane są pod względem trwałości, wrażliwości na światło i inne czynniki, z którymi może zetknąć się stworzona z nich biżuteria. Dzięki temu producenci znają zarówno mocne, jak i słabsze strony swoich wyrobów, co umożliwia im stałe doskonalenie produktów.

Pierwszym etapem stworzenia szklanych koralików jest oczywiście produkcja szkła. Miesza się odpowiednie proszki, aby uzyskać masę szklaną o pożądanej barwie i przejrzystości. Tworzone są koraliki przezroczyste, półtransparentne nazywane Cejlonem i nieprzejrzyste. Następnie całą mieszaninę ogrzewa się do ponad tysiąca stopni Celsjusza przez kilkanaście godzin.

Dokładnie wymieszane i stopione szkło formuje się w cienkie rurki z okrągłymi lub kwadratowymi otworami. Wielkość otworu regulowana jest poprzez powietrze wdmuchiwane w tłok. Następnie surowe szklane laski są sprawdzane. Testuje się, czy szerokość laski i średnica otworu są odpowiedniej wielkości. Pałeczki, które nie spełniają wymagań producenta, są ponownie topione. Dzięki temu minimalizowane są straty i redukowana jest ilość odpadów produkowanych przez firmę.

Kolejnym etapem jest cięcie szklanych rurek na identycznej długości koraliki. Później miesza się je z piaskiem węglowym i ogrzewa do 700 stopni w obrotowym piecu. Piasek zapobiega sklejaniu się koralików lub uszkodzeniu ich otworów. Kolejnym krokiem jest płukanie i polerowanie koralików na gorąco.

Na końcu koraliki są czyszczone i filtrowane zgodnie z ich rozmiarami. To kolejny element kontroli jakości. Koraliki przechodzą przez trzy rodzaje sit, najpierw spadają koraliki zbyt małe, potem te odpowiednich rozmiarów, a na końcu zostają za duże półfabrykaty. Zapewne domyślasz się, że koraliki o nieodpowiednich rozmiarach są ponownie przetapiane, aż osiągną wymiary idealne. Ostatnim etapem jest powlekanie koralików ich zewnętrzną warstwą. Ten proces różni się w zależności od wykończenia danego rodzaju koralików, a jego dokładny przebieg często owiany jest handlową tajemnicą.

Zapewne wiesz już jak bardzo cenimy koraliki Toho za ich jakość. Równe kształty ich koralików sprawiają, że utworzona z nich biżuteria ma profesjonalny i bardzo estetyczny wygląd. Co więcej, nie tylko wymiary zewnętrzne, ale także średnica otworu tych koralików jest idealnie równa, co znacząco ułatwia i uprzyjemnia ich nawlekanie. Bogaty wybór kolorów, wykończeń, rozmiarów i kształtów to także niekwestionowane atuty tych produktów.

Często nasze klientki porównują koraliki Miyuki i Toho, gdyż obie te marki słyną z produktów wysokiej jakości. Według naszego doświadczenia poza wyborem konkretnych kolorów czy kształtów koralików, które oczywiście różnią się pomiędzy markami, możemy znaleźć dwie różnice między tymi markami. Koraliki Miyuki cechują się największą na rynku precyzją rozmiarów. W przypadku Toho koraliki mogą różnica się ułamkiem mm między sobą, co w większości przypadków nie sprawia kłopotu, lecz może być widoczne przy dużych, precyzyjnych pracach na krośnie.

W porównaniu do koralików Miyuki Toho ma jedną bardzo obiektywną przewagę. Niska cena koralików Toho jest ich zdecydowanym, dodatkowym atutem. Dlatego też polecamy je szczególnie wszystkim początkującym i amatorskim rękodzielniczkom.

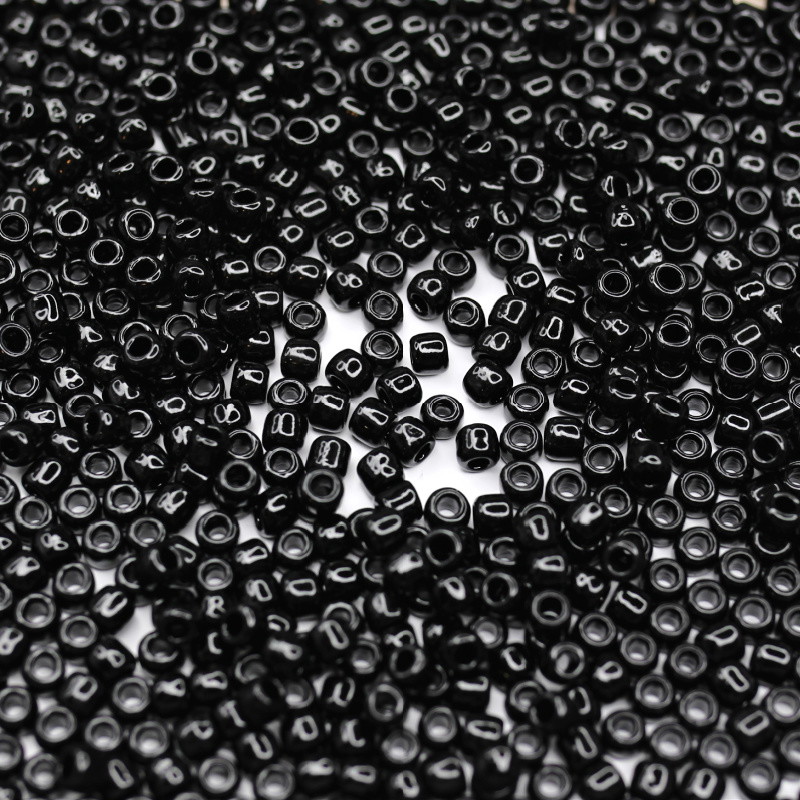

Koraliki Toho możemy podzielić ze względu na kształt, rozmiar, przejrzystość, czy rodzaj wykończenia. Najczęściej stosowanym podziałem jest ten pierwszy lub drugi. Wśród kształtów koralików Toho możemy wyróżnić:

Rozmiary koralików Toho są podobne jak w przypadku innych japońskich koralików ze szkła. Rozmiar 15/0 to najmniejsze koraliki tej marki dostępne w naszej ofercie, a ich średnica wynosi około 1,5 mm. W przypadku największych koralików, czyli 3/0 średnica to około 4,3 mm. Rozmiarówka tych koralików odnosi się do tego, ile sztuk zmieści się na odcinku o długości 2 cm. Ułatwia to planowanie projektów, szczególnie w przypadku skomplikowanych wzorów.

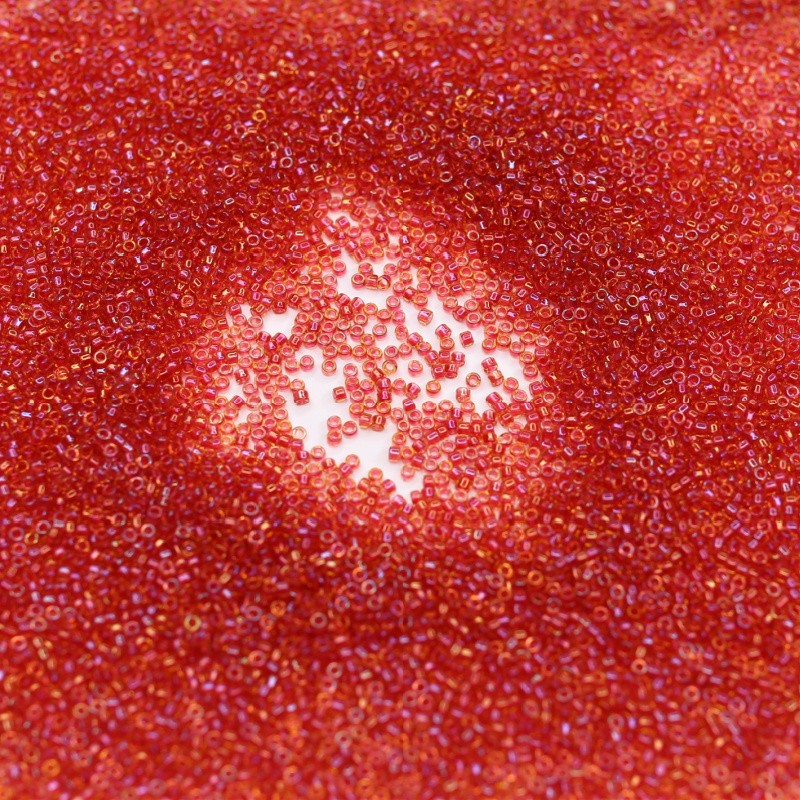

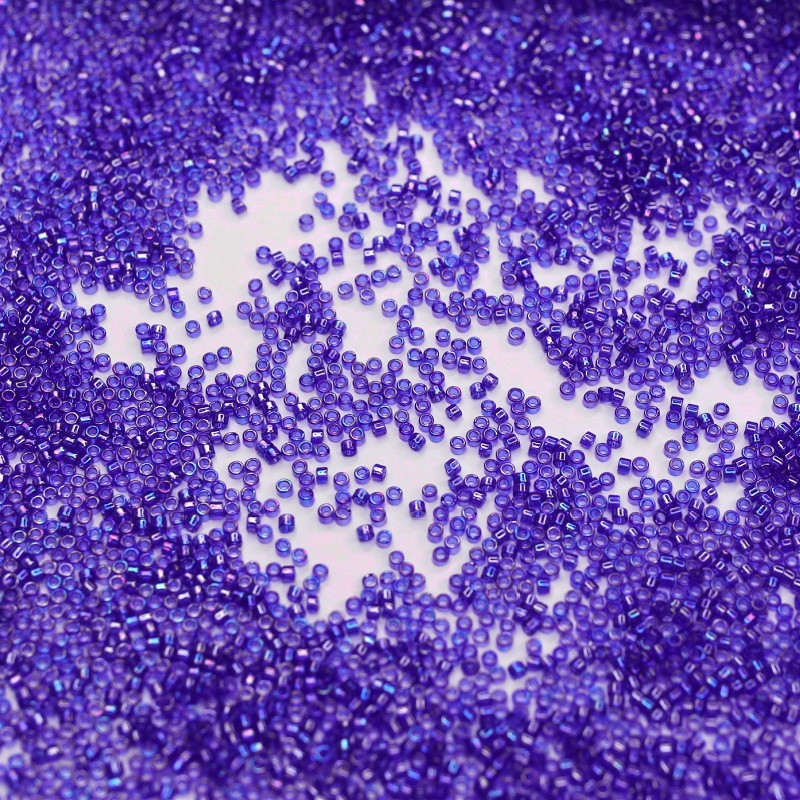

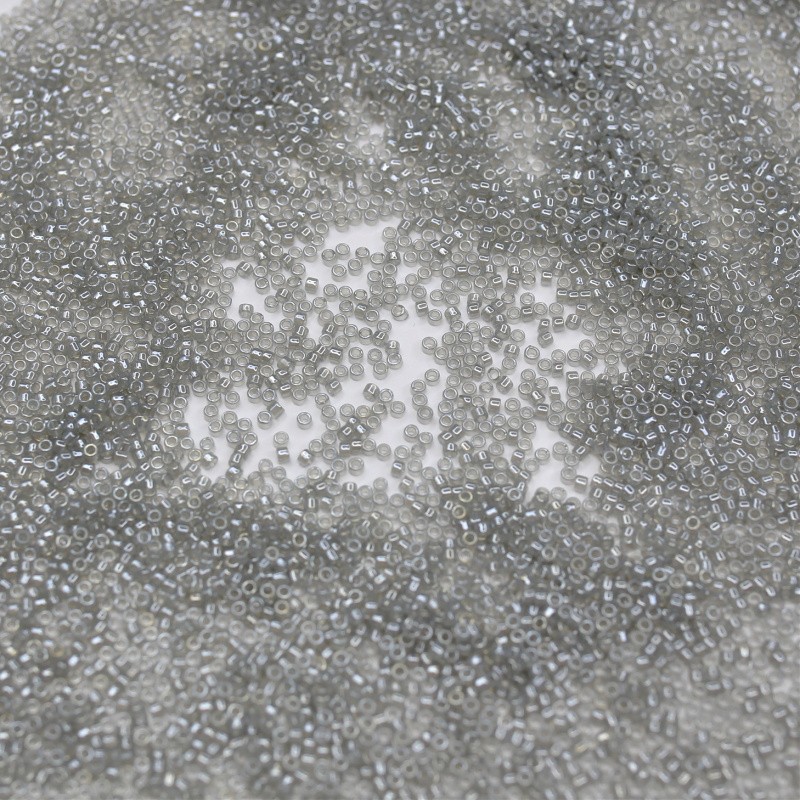

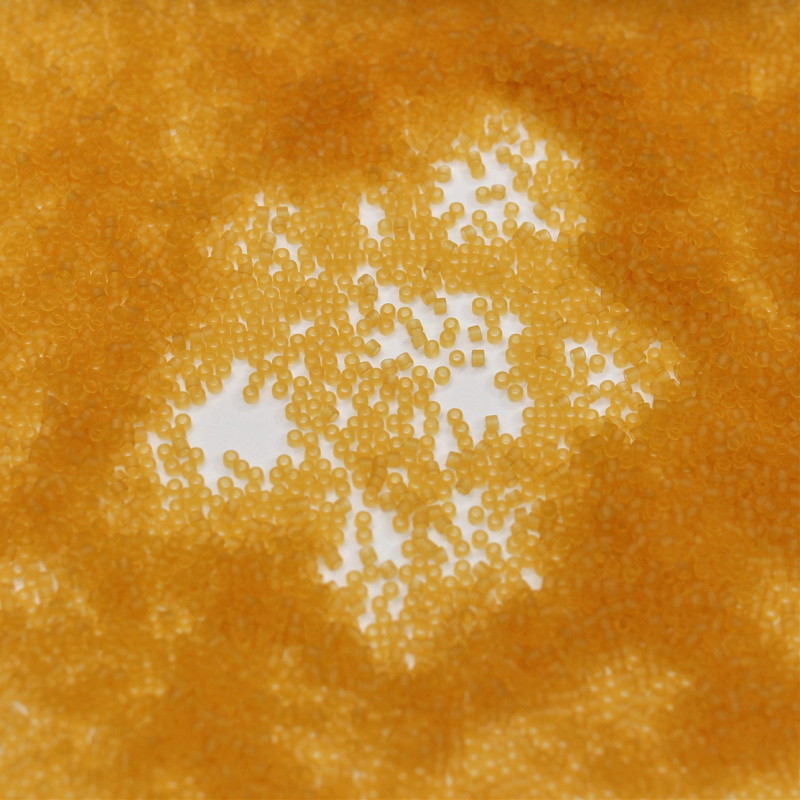

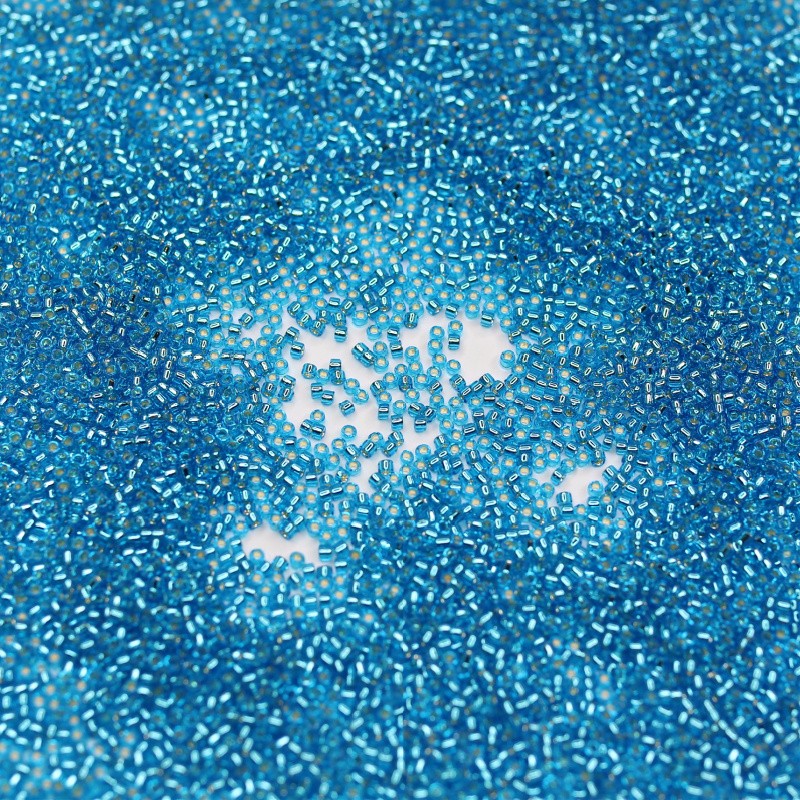

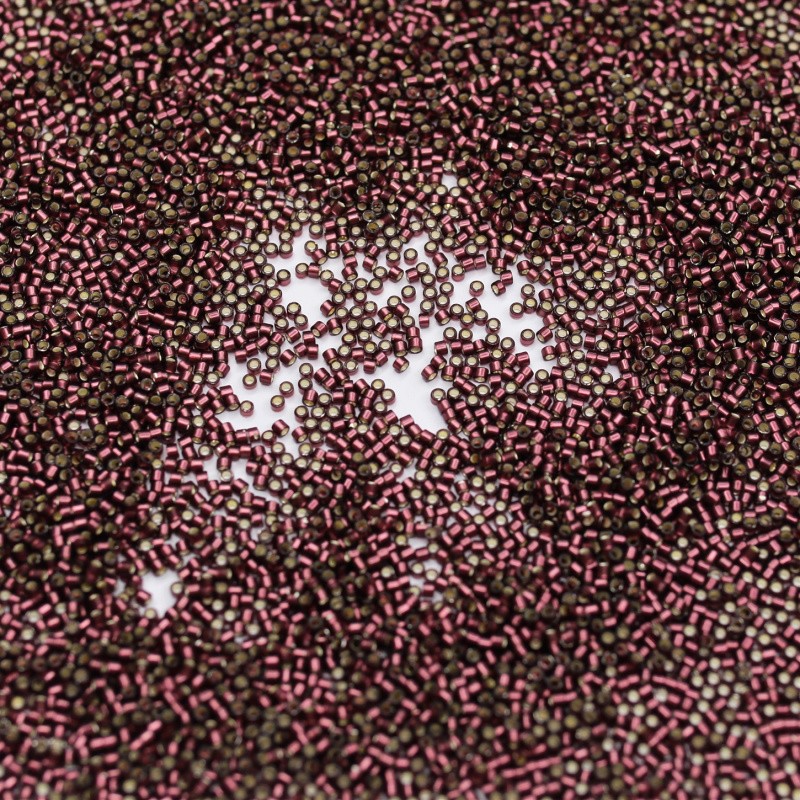

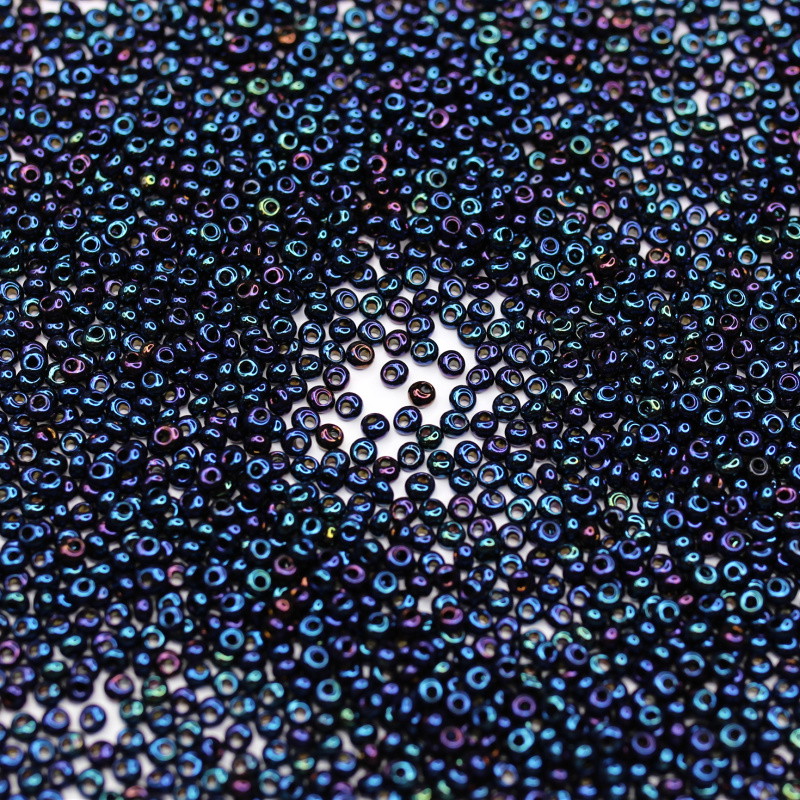

Wszystkie rozmiary i kształty koralików Toho znajdziesz w dziesiątkach różnych barw i wykończeń. Niektóre pokryte są tęczową, lśniącą powłoką. Inne wyścielone są metaliczną lub kolorową powłoką od wewnątrz koralika. Metaliczny blask może być także efektem zewnętrznego wykończenia koralika. Co więcej, koraliki Toho znajdziesz w wersji błyszczącej wypolerowanym szkłem, lśniącej metalem lub perłowe, jak i matowej. Nasz sklep z koralikami oferuje tak ogromny wybór tych szklanych koralików, że nie sposób opisać je wszystkie. Dzięki temu mamy pewność, że znajdziesz wśród nich półfabrykaty idealne do wymarzonej przez Ciebie biżuterii.

Możesz wykorzystać je w każdej beadingowej technice od peyote, przez różne ściegi po tkanie ręczne i na krośnie. Dodatkowo koraliki Toho doskonale sprawdzają się w sutaszu. Z powodzeniem ozdobisz nimi torebki, odzież i buty. Możesz nawlekać je na dowolne półfabrykaty takie jak

Warto pamiętać, że koraliki Toho można wykorzystać w roli przekładek w towarzystwie innych koralików ze szkła, kamieni, pereł, czy surowców sztucznych. Dzięki ich niewielkim rozmiarom nadają się do dosłownie każdego rodzaju biżuterii od pierścionków, przez kolczyki i bransoletki po naszyjniki. W skrócie koraliki Toho są trwałe, piękne i wszechstronne. Pozostaje tylko tworzyć z nich biżuterię i cieszyć się nią każdego dnia.